Smart Seams

part 1 part 2

Thanks to the quality and price indicators of feather-down insulation, sewing products based on it have become an excellent alternative to expensive fur products. But fluff is a capricious insulation.

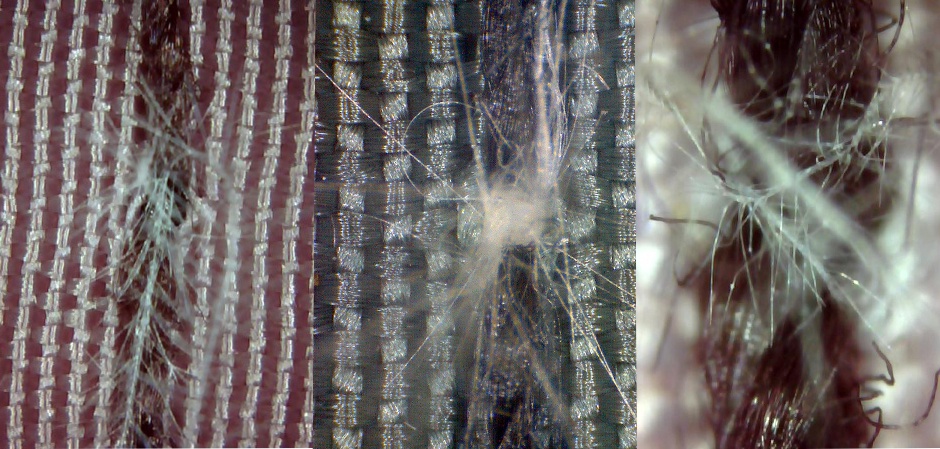

According to experts, the main problem faced by manufacturers of down jackets is the migration of the down mixture through the holes formed when the material is pierced with a sewing needle during manufacture. This phenomenon cannot be avoided by consumers during the operation of products.

A study of technologies used all over the world has shown that in the production of garments on down insulation for household and special purposes, there are no other methods of connecting parts other than thread, it is universal and provides the necessary strength, but the seams as a result of perforation of the package of materials are permeable to fluff, therefore their sealing treatment is necessary. Now there are a large number of technological solutions aimed at improving the tightness of seams. However, there is no scientifically proven method for choosing a specific method of high-quality connection of parts. This leads to low efficiency of technological sealing processes, that is, high labor and material intensity, technical complexity of implementation, limitation of the field of use, danger to the environment, and so on.

The technology of gluing with a special nanostructured adhesive film material of the places of the thread connection of clothing, developed by Smarttex and used in the production of down jackets produced under its own brand, eliminates the migration of down. The film material (its working name is smartscotch) is able to penetrate into the hole and fill it, because it has viscous-fluid properties, due to which the migration of the feather-down mixture is blocked through punctures. It is absolutely harmless to health, as it consists of acrylate latex, so it can also be used in the production of children's clothing.

The main advantage and the main difference between the technology of manufacturing down jackets using smartscotch is the presence of a permanent residual stickiness, which allows it to be connected to the upper material without heating and increased pressure. Moreover, no additional equipment is required for gluing a smartscatch – a minimum pressure comparable to the presser foot of a sewing machine is quite sufficient.

Of course, there are technologies in the world that are inherently similar to the one described. However, most often they are based on the use of thermoplastic adhesive materials, that is, for their implementation, not only auxiliary materials are needed, but also special equipment that provides a hot air jet (about 600 °C), which must be additionally equipped with an expensive compressor.

The hot-glue method of sealing joints is currently increasingly replacing the fire-hazardous, toxic, time-consuming, non-mechanized method of sealing with the use of auxiliary tapes glued to the surface of the seams using thermosetting glue.

To be continued.

Author: Elena Dyakonova, Head of Research and Development Works of Smarttex LLC

Photo: LLC «Smarttex»