Shoes that always fit

part 1part 2

Even very accurate measurements do not guarantee 100% shoe comfort. A person's feet deform during any physical activity, and this affects the comfort of wearing shoes. With a regular fitting in a store, it is almost impossible to calculate the degree of comfort in motion. The InMotion technology of Tryfit Technologies allows you to simulate the wearing of shoes for various types of activities, such as running, jumping, walking and others.

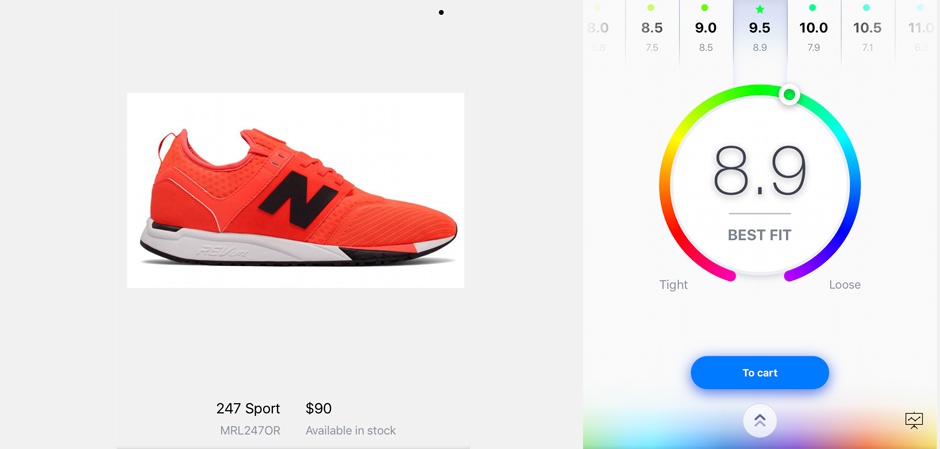

Using the Fit Rate technology, Try.Fit evaluates the compliance of shoes with foot parameters on a scale from 1 to 10. When rated below 6.5, shoes are considered uncomfortable. A score of 10 is rare. Usually this value corresponds to custom-made shoes. But if the degree of comfort is higher than 8.5, the buyer can be sure that it will be comfortable in shoes.

Soon it will be possible to get a 3D image of the foot not only by visiting the store, but also using a mobile application: the buyer needs to put a black sock on the foot, put the foot on a white sheet of paper and take a photo from three different angles. The resulting three-dimensional image will allow you to select shoes with a fairly high degree of accuracy, although the measurement error will be slightly higher than when scanning in the store.

1C has invested more than 250 thousand euros in Try.Fit. It should be understood that Try.Fit sells a service, and scanners act as terminal equipment that is provided as part of the service.

Try.Fit is not the only company presenting virtual shoe fitting technology on the market. In 2014, the Fraunhofer Society's German Integrated Circuit University (Fraunhofer IIS) invented a way to scan and recognize shoe size without opening boxes. The system is called Mifitt and works like an X-ray: the boxes are translucent, about 20 key points are fixed inside. Using these points, you can actually completely build a simplified virtual model of each pair of shoes. This virtual impression is entered into the database. Now data on 1.7 million pairs of shoes are already stored there. Having measured the client's foot, Mifitt can select the right model from the database. A 3D scanner has also been created for this measurement, but it takes into account fewer parameters than Try.Fit. For example, it does not take into account such a value as the rise of the foot.

But in Spain, Professor Juan Carlos Gonzalez from the Institute of Biomechanics of the city of Valencia has developed a special smartphone application that allows you to create a 3D model of your own foot with just three pictures. Thanks to this technology, any smartphone can turn into a kind of 3D scanner. In addition to creating a 3D model, the application gives the user more than 20 parameters of his foot, which help in choosing shoes. A three-dimensional image can be uploaded to an online store and thus virtually "try on" the shoe model you like. The Spanish researcher has also developed an autonomous DOMEscan device that determines the parameters of the foot. It can be used in shoe stores.

At the Moscow State University of Design and Technology, at the Department of Artistic Modeling, Design and Technology of Leather Products, an apparatus has been created that scans the foot with a laser and, based on the data obtained, designs an individual shoe pad - the basis of future shoes.

Technology does not stand still. Competitors do not stand still either. While the 3D scanner market is not saturated, there is a reason to think about a profitable business model.