Russian flax

Advantages of long flax

Flax is the most important technical culture of strategic importance in Russia, which allows to ensure import substitution of cotton to a large extent. Flax fiber is used to produce a large range of clothing, medical and technical fabrics with unique consumer properties. Flax products are superior to cotton in terms of a complex of physical and mechanical qualities. Linen fabrics have improved hygienic properties compared to cotton. Flax products, taking into account their high strategic value, can be widely used for defense purposes. Flax fiber is the most important product for the production of special materials, as well as heavy-duty and lightweight carbon fiber plastics. Linen clothing and bed linen are 3-4-fold savings on their purchase by increasing the duration of use of these goods compared to cotton analogues, as well as providing protection from moderate ion radiation. The use of flax products in strategic sectors of the economy makes it possible to increase its liquidity in the domestic market by at least 2 times, save significant financial resources, strengthen the economic security and raw material independence of the country.

"Flax and its processed products have longer terms of use, have high strength, high environmental characteristics. And raw cotton is a 100% import, moreover, it is getting more expensive, notes Andrey Razbrodin. These factors alone determine the competitiveness of industrial flax cultivation and its deep processing. Plus, flax growing is also the prevention of degradation of empty agricultural land in about a third of the country. While cotton cultivation is possible only in some areas of the Lower Volga region and the North Caucasus from the point of view of the maximum return from this sector of agriculture.

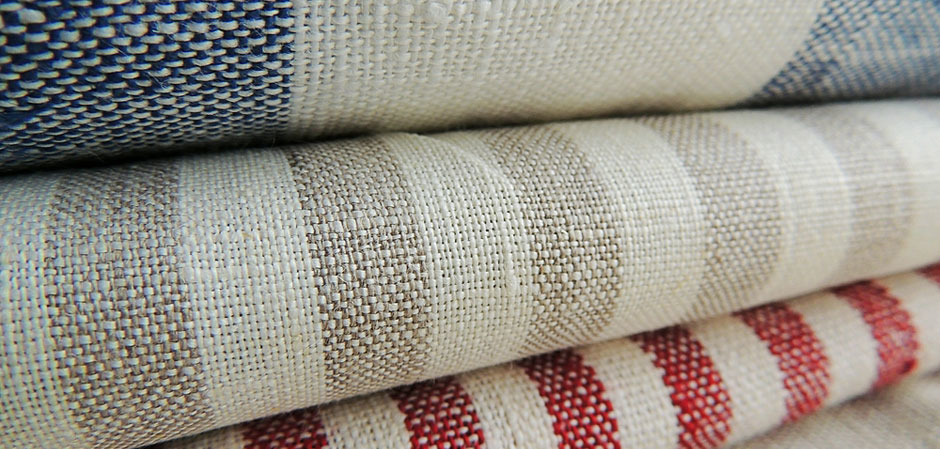

Trending fabric

Flax production in Russia has deep cultural and historical roots. However, in the new century, there are obvious problems with the adaptation of linen fabrics and products to modern trends.

Due to the lack of modern high-tech equipment at flax processing, textile (weaving) enterprises, about 60% of linen fabrics in the country are produced in the form of semi-finished products (without the necessary design). Linen and flax-containing fabrics, in comparison with cotton, have a reduced breaking load due to the sparsity of its structure, higher shrinkage after wet processing. They are more expensive than cotton analogues, which narrows consumer demand for clothing and other goods obtained from them, especially among young people who, as a rule, have small incomes. The trend of consumer demand for linen products is shifted towards the wealthy part of the population with high and average incomes.

The Ministry of Education and Science, the Ministry of Industry and Trade and the Ministry of Economic Development of Russia need to consider possible mechanisms for introducing school uniforms made of flax, including from the point of view of ensuring the preferential participation of domestic producers in providing school institutions with such uniforms.

"I have already noted that flax processing products are increasingly widely used in various industries," says Andrey Razbrodin. Modern technologies allow us to produce linen products that are fully adapted to the needs of high-tech sectors, for example, the military-industrial complex, dual-use industries. Moreover, in many countries this direction has been developing since the 1970s.

Consumer demand for flax products remains high both in Russia and abroad. Figuratively speaking, not only young people, but also other social groups seem to be "tired" of synthetics, which have dominated the light industry product markets since the 1980s. Again, the high level of environmental friendliness of linen products, and a wide range, and their durability are the main factors of high demand. Even despite the fact that a significant part of the linen assortment is more expensive than synthetics. It can be said that the consumer "votes" for useful products, and this applies not only to light industry products.

Text: Svetlana Michan

Photo: shutterstock