Next generation materials: on the way to mass production

The annual exhibition Future Fabrics Expo demonstrated both the difficulties faced by startups in the field of innovative materials development and their enthusiasm. Hundreds of exhibitors, eager to scale up and reduce the negative impact of the fashion industry on the environment, gathered in London. However, this year the atmosphere was different.

The industry's attention to the problem has become sharper. The day before the exhibition, a report was published, supported by Kering and The Laudes Foundation, which describes in detail the obstacles to growth. These include:

- Limited investor awareness in the field of fashion materials.

- Oversaturation of the market: Startups seem similar to each other.

- Lack of long-term commitments from major brands and suppliers of raw materials.

The publication Vogue Business gathered the participants of Future Fabrics Expo to discuss these barriers and ways to overcome them.

Hannes Schonegger, Co-founder and CEO Bananatex:

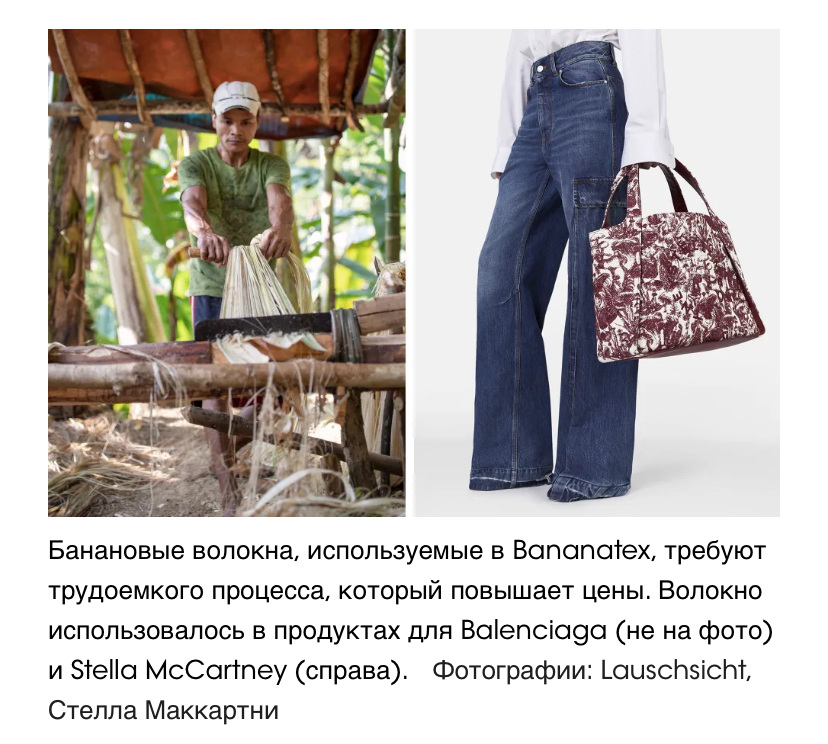

Bananatex manufactures fabric made from banana abaca fibers and cooperates with brands such as Stella McCartney, Balenciaga and H&M.

The extraction of banana fibers in the Philippines was already established, so there was potential for scaling. The only problem was the price. Fiber extraction requires a lot of manual labor, and it is impossible to automate this process. One worker can produce 1 kg in an hour or 10 kg in 10 hours, which makes scaling unprofitable.

This has become a problem for brands, as Bananatex is twice as expensive as organic cotton and more than four times more expensive than polyester. Luxury brands with higher margins find it easier to cope with such a price, but in general, brands are not willing to pay for eco-friendly materials.

OnceMore: Overcoming barriers to sustainable fashion with recycled textiles

OnceMore, a subsidiary of Sweden's largest forest owners association Södra, uses chemical recycling to create an alternative to viscose from textile waste from polychlopk and wood. At the Future Fabrics Expo, OnceMore shared its experience in overcoming barriers to the introduction of more sustainable materials in the fashion industry.

First, the company actively seeks cooperation with brands that share their values in the field of sustainable development, while providing brands with detailed information about their materials, including data on origin, environmental impact and product characteristics.

Secondly, OnceMore strives for long-term relationships with brands, not one-time projects. The company uses examples from other projects to help designers imagine how the final products from their materials will look and feel.

It is important to note how OnceMore dispels doubts about recycled materials by demonstrating their quality and versatility. OnceMore demonstrates that with open dialogue, transparency and illustrative examples, barriers to more sustainable fashion with recycled materials can be overcome.

Andre de Castro, Beleaf Marketing Director, on cooperation with fashion brands:

"Beleaf is an innovative material created from the leaves of the plant Alocasia Macrorrhiza. Our Brazilian company Nova Kaeru has already collaborated with such well-known brands as Loewe, Botter and Christopher Esber.

Working with big brands is always a challenge. Bureaucratic procedures and the need to coordinate with multiple departments can slow down the process. However, it is precisely these difficulties that make collaboration with brands so valuable. Such companies strive for excellence and are ready to invest in product development. Thanks to the partnership with brands, we were able to improve our material. For example, new substrates have been developed to increase flexibility and formulas have been modified to expand the scope of application. As a result, we have created a line of materials that mimic the texture of bovine leather, while preserving the unique properties of the leaves.

However, it is important not to forget about the original idea. We tried to create a material that preserves the natural shape and beauty of the leaves. Therefore, with all innovations, we try to stay true to this concept."

Mira Namet, head of Biophilica, talks about her innovative material Treekind — an environmentally friendly alternative to leather made from leaves. The company received the prestigious Cartier "Forces for Good" award and a grant of 100,000 euros.

Namet emphasizes the importance of phased introduction of innovative materials into the fashion industry. Brands often strive to create the perfect product right away, but this is not always effective. It is better to start with small changes and gradually improve the material.

Financing innovation in sustainable fashion also needs to be reviewed. Existing venture capital models focused on quick returns are not always suitable for long-term research in the field of materials science. Namet offers a more distributed financing model where several companies can work together on technology development and share knowledge.

The problem of "ghost" brands is another difficulty faced by innovators. Brands often show interest in new materials, but then disappear without explanation.

Claire Lichfield, co-founder of Sequinova, creates eco-friendly cellulose sequins that completely decompose in water in just a few weeks. The company is now actively implementing its production. To accelerate the development of such innovative materials, governments could support startups more, for example by providing grants and encouraging brands to use greener solutions. Brands, in turn, should unite in order to reduce the cost of new materials and overcome the fear of being the first.

Stephanie Downs, co-founder and CEO of Uncaged Innovations, spoke about the difficulties the company faces in producing vegan skin from grain proteins.

The main problems:

- Finding production partners: Traditional tanneries focused on mass production are often reluctant to undertake pilot projects with new materials.

- Financing: Despite the growing interest of investors in sustainable technologies, it is still difficult to find financing to scale the production of vegan leather. Investors are demanding convincing evidence of demand from big brands.

The production of innovative materials requires significant investments and partnerships. Brands play a key role in the development of the vegan skin market by investing in research. Uncaged Innovations is looking for brands willing to invest in the development of new materials and enter into long-term agreements, and the company, in turn, offers brands to pay for the development of prototypes to offset the costs of research and development.

Lacey Davidson, Marketing Director at Ecovative, talks about how the technology firm Mycelium Ecovative, founded in 2007, initially developed skin based on Mylo mushrooms in collaboration with Bolt Threads. Today, the company cooperates with the Veshin Factory to enter the market of its unique mycelium material.

The main obstacle to scaling is the need to refine the material so that it meets the brand standards. In this regard, they initiated cooperation with the Fashion for Good cooperative, created jointly with Bestseller and PVH Corp, which provides an open feedback channel with several brand partners at the same time. Since then, the cooperative has expanded to include companies such as Reformation, Vivobarefoot, Pangaia and Wolverine Worldwide, among others who have chosen to remain anonymous. Whereas a few years ago our laboratory team needed more than 12 months to complete experiments leading to noticeable performance improvements, now this process takes only a few days.

Scaling next—generation materials is a complex task that requires an integrated approach. To successfully solve this problem, it is necessary to continue to search for new materials and improve existing technologies. Create production infrastructure and logistics chains for new materials. To combine the efforts of government agencies, business and scientific communities, and it is also important to raise awareness of the benefits of new materials and encourage their use.

Do you want to keep up to date with the main events in the fashion industry and brand news?