Dry means comfortable

The problem of getting wet insulated clothes arose in front of a person from the very moment of its appearance. In the last century, it was solved by extremely simple methods: it was dried or frozen. The hygroscopicity of natural fibers of plant or animal origin, which were then used in the production of insulation materials (mainly batting and various wool insulation materials), simply left no other way out. However, the new century has come with new technologies.

Synthetic insulation materials with zero hygroscopicity of fibers appeared. And since that time, the views of manufacturers of insulated clothing have changed. Today it is believed that the insulation must be dry. Let's try to figure out why?

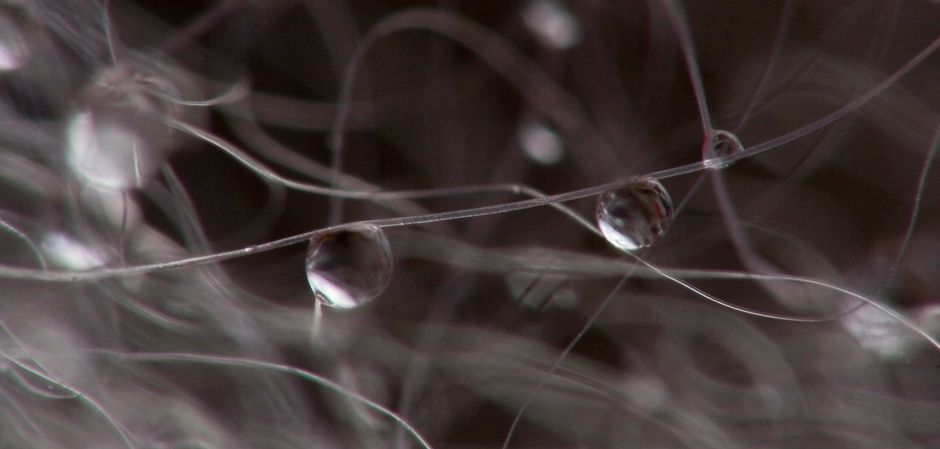

But first, let's look into tomorrow. Textile exhibitions at the end of 2016 – beginning of 2017 announced the trend of water repellency. Under this complex term lies the property of repelling water, which is understandable to everyone. If, for example, it does not cause surprise on the film in the bathroom, then fibrous insulation materials with such a feature are still a real curiosity. Nonwovens, which are conventionally called "approx. z", not only do not absorb and retain moisture in the fiber, but also repel drops. If you visually try to imagine the behavior of a drop of water on such a material, then this is how mercury behaves on a smooth surface. The main consumers of such developments are manufacturers of lightweight, breathable, practical and modern outdoor clothing. The materials of this high-tech future have the function of air exchange ("breathable" properties), and moisture does not penetrate into the insulation layer, leaving it dry in normal operating conditions. The essence of the water repellent effect is as follows: in the new generation heaters, special types of fibers are used that repel water: intermolecular bonds work on the principle of the difference in magnetic fields.

These latest developments have become possible for only one reason: the materials and approaches to the creation of insulated clothing have changed. As you know, moisture is the main conductor of heat. Wet clothes are cold clothes. It loses the main function of protecting from the cold. Even slightly moistened clothes are uncomfortable, unhygienic. It sounds like a paradox, but in fact the moisture in the clothes is held by the fibers from which it is created. This affects not only the thermal conductivity, but also the quality characteristics of the products. Back in the 70s, the Soviet school of Materials Science formulated the principle: "The higher the performance properties, the less moisture the fiber is able to absorb...» (Z. A. Rogovin. Fundamentals of chemistry and technology of chemical fibers). It took decades for us to be able to say today: the insulation must have zero hygroscopicity in order to... be a heater.

According to the head of the SIC "Clothing", Candidate of Technical Sciences Lyudmila Kirillova (Central Research Institute of the Garment Industry), the basic foundations for the research of insulating materials were laid back in the 70s by the school of Professor P. And Kolesnikov (at that time director of the Institute). To date, they are interesting only from the point of view of analyzing the properties of insulation.

The technical base in the 70's and 80's was focused on the creation of insulated clothing using materials mainly made of natural fibers. Then, in the course of research, it was found that a certain stable microclimate is needed under clothing, the constituent elements of which are temperature, humidity, air mobility, carbon dioxide content. These requirements can be met only when using materials in clothing with an optimal indicator of such properties as air permeability, moisture conductivity, vapor permeability, hygroscopicity, thermal resistance. The provision on hygroscopicity of natural insulation materials was taken as a basis. Paradoxically, they were already trying to get rid of it in various ways. Experimental work has even been carried out to reduce the effect of capillarity in fibers of plant and animal origin. For the first time in 1974, a very cautious and restrained statement was made: "...high hygroscopicity of chemical fibers is not necessary.

Several decades ago, there were suggestions that the insulation should not be a sorbent and even a slight moisture content leads to a loss of thermal protection of clothing. But the limited range of textile materials, reduced mainly to wool-containing and cotton-containing insulation materials, practically paralyzed the solution of this problem for almost 40 years.

Nowadays, high-tech synthetic insulation has appeared. Having numerous data from studies of such materials conducted in recent years, we can say that the "certain stable microclimate" noted by expert L. Kirillova depends most on the humidity of the insulation (its hygroscopicity, sorption and capillary features).

Moreover, all other noted indicators, such as air permeability, moisture conductivity, vapor permeability, thermal resistance, are in direct relationship and interdependence, where the main catalyzing factor is hygroscopicity.

To be continued.

Author: Vladislav Ivanov,

Director of plant development «Thermopol», (TM "Holofiber").

Photo: Shutterstock.com